Ultrasonic Oxide Thickness Measurement

Oxide Scale Thickness Measurement

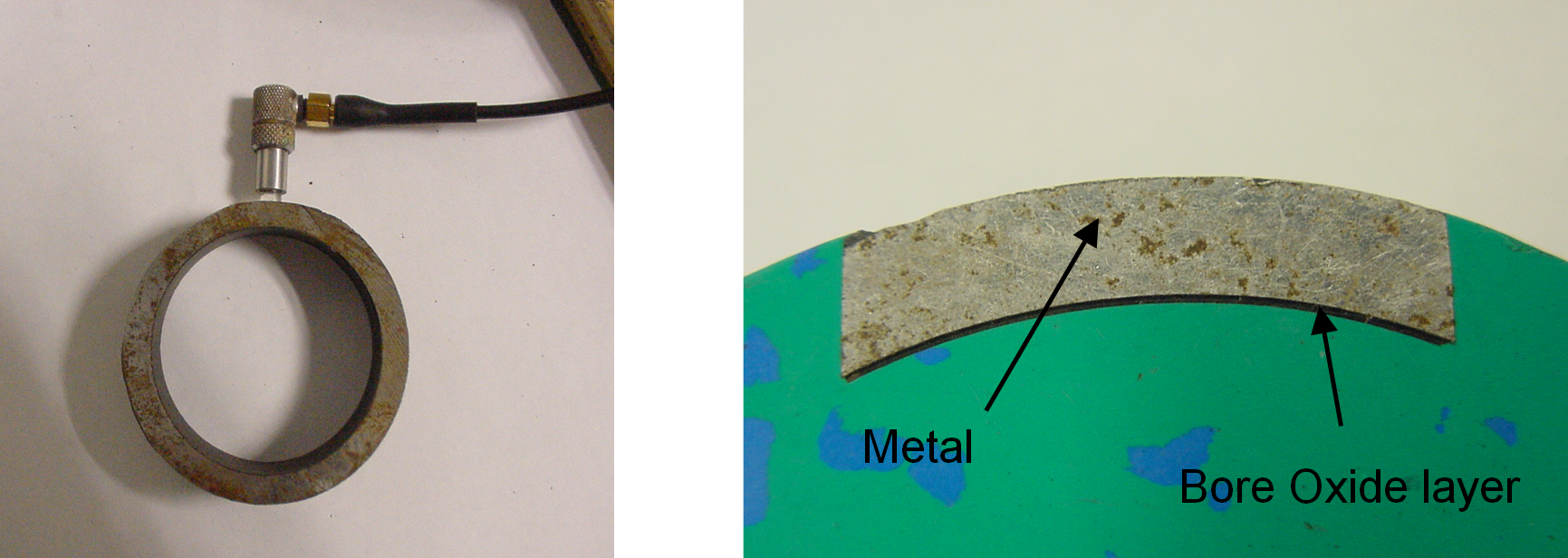

The Challenge -The formation and growth of iron oxide scale on the inner and outer surface of boiler tubes is a significant factor affecting tube life. The high-temperature regions of steam boiler can cause the formation of surface ‘grown oxide’ (Magnetite) which forms progressively under long term exposure to high temperature.

The conductivity of the oxide scale is approximately 5% that of the steel, and as the grown oxide layer builds in thickness over time, it forms to acts as a thermal barrier on the surface. The resultant loss in heat transfer leads to the tube wall heating, to temperatures beyond the intended operating range. Long term exposure to raised temperatures and high internal pressure, can result in micro-cracking within the tube wall and to creep deformation and eventual failure.

Integrity NDT Solution – To determining the oxide layer thickness, Integrity NDT are using a high frequency delay line ultrasonic probe typically (Single crystal delay line compression wave probe 20MHz 0.125mm), and broadband digital UT flaw detector. The flaw detector must be capable of detecting echoes and measuring the short time interval between the peaks, representing a) the steel/oxide and b) the oxide/air boundaries.

In consideration that bore oxide thickness ≥300 microns is the threshold at which operational problems (tube conduction efficiency, overheating, spallation & blockage etc.) are likely to start manifesting themselves, oxide thickness measurements of this level and below (down to 125 – 150 microns) can be achieved ultrasonically, and avoid the need for tube cutting. Additionally, the fact that oxide thickness is proven to be proportional to tube operating temperature, gives non-destructive Oxide thickness measurements the potential to target ‘hotter’ (shorter creep life) tubes for replication across a header bank for example, if conducting creep life assessment.